Engineered Yeast As a Method for Bioremediation

This technology is an engineered yeast bioremediation tool that has potential uses in environmental cleanup and mining.

Researchers

-

engineered yeast as a method for bioremediation

United States of America | Granted | 11,884,566 -

engineered yeast as a method for bioremediation

United States of America | Granted | 10,766,798

Figures

Technology

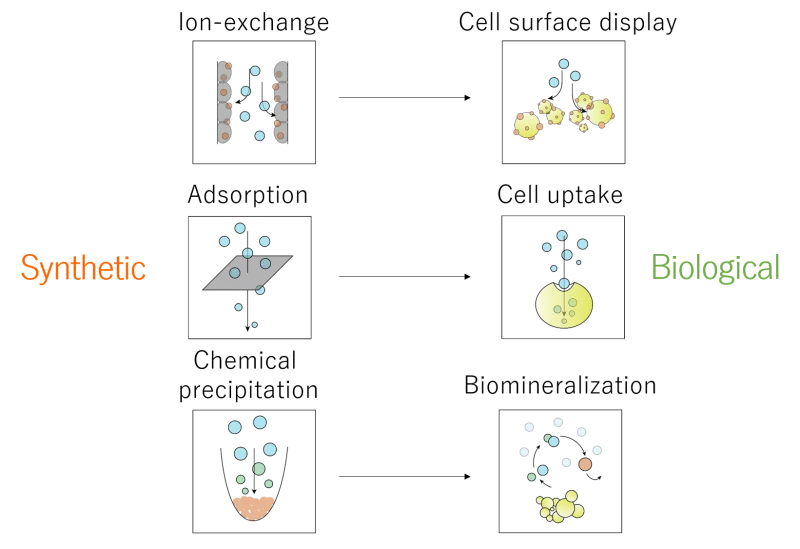

These inventors have developed three techniques to remove heavy metal waste including cell surface display of metal binding proteins, cellular uptake to capture metals, and biomineralization. The first technique uses a secreted fusion protein of glutamine synthetase (GS) and metallothioneins (MT). GS has a unique ability to form complex scaffolds in the presence of divalent metals. Metallothioneins are plant-based proteins that have specific metal binding capacities. When these proteins are secreted as a fusion protein along with yeast expressing surface displayed GS, they efficiently bind heavy metals in solution and form dense yeast-metal aggregates that are easily removed from the water. The second metal remediation strategy uses direct metal uptake into the yeast using transmembrane metal transporters. These inventors performed successive rounds of mutagenesis and selection on the yeast metal transporter SMF1 and successfully generated SMF1 transporters that specifically and efficiently uptake cadmium, lead, and strontium. The final bioremediation technique these inventors use is biomineralization of metals. Sulfur is a reactive element that can react with metal ions to form inert metal sulfides. Sulfur has been used in industrial chemical precipitation; however, the volatility of sulfur makes it hazardous to store. Sulfur is a necessary element for life, and biochemical sulfur assimilatory pathways are required to make sulfurous amino acids. These inventors engineered yeast with a strategic block in a sulfur assimilatory pathway that leads to sulfur buildup. This sulfur producing yeast are very efficient at precipitating copper, cadmium, zinc, lead, and mercury, into dense aggregates in the yeast cell membrane. Together, these technologies provide a diverse array of metal remediation strategies.

Problem Addressed

Heavy metal pollution is a major threat to the environment and human health. Runoff from industrial manufacturing, consumer waste, and mining sources are major contributors to heavy metal pollution of waterways. Current methods for removing heavy metal contamination are expensive to develop and manufacture and are themselves often prone to forming waste by-products. These inventors have engineered metal consuming yeast as a bioremediation technique to remove heavy metal contamination from water.

Advantages

- Metal bioremediation technique using genetically engineered yeast

- Autonomous, non-reactive, non-toxic metal remediation

- Customizable metal specificity and metal uptake sensitivity

- Scalable production using techniques established in brewing and wine industries

- Simple storage of dried yeast

- Translatable to rare metal mining applications

License this technology

Interested in this technology? Connect with our experienced licensing team to initiate the process.

Sign up for technology updates

Sign up now to receive the latest updates on cutting-edge technologies and innovations.