Printing of Carbon Nanotubes in Fluids

With increasing dependence on technology there is a growing need of more efficient methods of power generation, transmission, and conversion. Printing of elongated nanostructures through extrusion-based additive manufacturing allows for the fabrication of planar and three-dimensional (3D) features and objects that are incorporated into specialty electronics, power transformers, and high-frequency wireless transmitters and receivers.

Researchers

-

systems, devices, and methods for direct-write printing of elongated nanostructures

Patent Cooperation Treaty | Published application

Figures

Technology

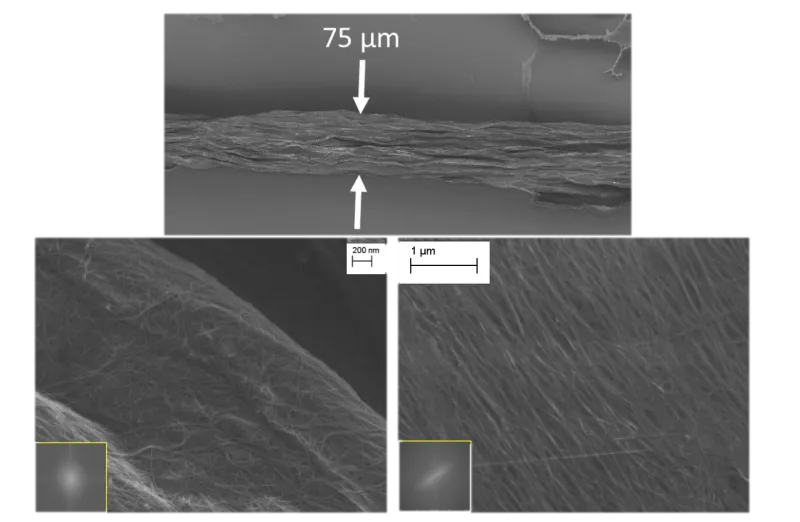

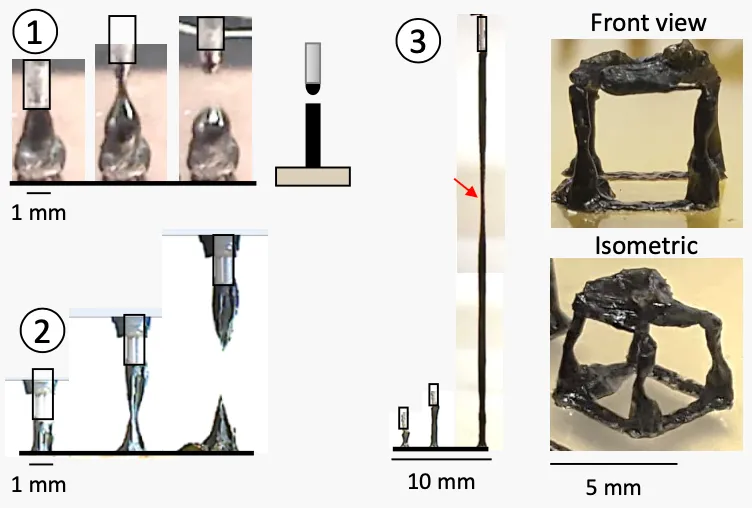

The invention is directed to tailoring the structure of freeform CNT macrostructures through extrusion-based additive manufacturing for fabrication of planar and three-dimensional features and objects. Ink containing nanomaterials can be extruded into a fluid to precipitate into a fiber that can be used to form solid structures. The fluid can include a coagulant that promotes rapid solidification in the precipitation of fibers. The fluid can be disposed into a bath that is in fluid communication with the extruded ink. The printed and precipitated solid can have tunable properties and achieve macrostructures of melt pools, necked tips, or elongated free form objects.

Problem Addressed

Disadvantages of existing 3D printing techniques include limited customization of properties across a surface area and do not produce robust mechanical properties. Resistive losses resulting from material property limitations are a major source of inefficiency for many power conversion and generation devices. To reduce these losses, lower weight and higher conductivity materials are necessary. Carbon nanotubes (CNTs) and similar elongated nanostructures achieve these material properties, but only at the nanoscale. Macrostructures of these elongated nanostructures have failed to achieve the properties of their nanoscale counterparts through existing 3D printing techniques.

Advantages

- High electrical conductivity per density

- High thermal conductivity, even at elevated temperatures

- High current-carrying capacity

- High tensile strength

- Great corrosion resistance

- Low overall production costs and simple processing

License this technology

Interested in this technology? Connect with our experienced licensing team to initiate the process.

Sign up for technology updates

Sign up now to receive the latest updates on cutting-edge technologies and innovations.