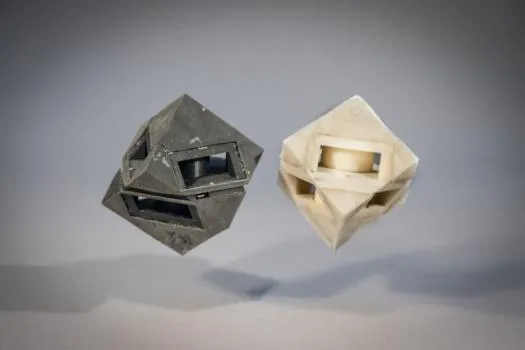

Printable Programmable Viscoelastic Materials

The Inventors demonstrate a new method for 3D printing viscoelastic materials (PVMs) with specified material properties that minimize impact and vibration. This technology has many applications to design and print robotic devices in industries ranging from commercial to medical or aerospace manufacturing. Customized impact protection could allow robots to be more resilient, accurate, and reduce controller complexity and effort. The vibration damping properties of PVMs can be used in traditional hard robotics to protect sensitive devices such as cameras and electronics from the vibrations of motors, generators and movement.

Researchers

-

additive manufacturing of viscoelastic materials

United States of America | Granted | 11,052,597

Figures

Technology

The Inventors modify a commercially available inkjet 3D printer to modified to simultaneously print with different solid and liquid materials. Via hydraulic pressure, a liquid material alongside a flexible material is continuously distributed with adjacent droplets of each material type. Multi-material objects fabricated in this manner are specified by an occupancy matrix. The entries of this matrix correspond to the voxels of the part that will be built. Materials with mechanical properties that differ from the base materials can be specified by assigning different fractions of randomly chosen voxels to one material type or another, assuming that the chosen voxels lie within the bounding surface of the part that will be fabricated. This approach allows customized PVMs to be designed and fabricated based on an algorithm that factors in whether the viscoelastic material is likely to be used in small or large deformations. Vibration damping applications typically fall into the former category, while impact absorbing cases fit the latter. The desired material property is chosen, and the liquid percentage is generated based on an algorithm developed by the Inventors.

Problem Addressed

Impact protection and vibration isolation are an important component in mobile robot design. However, current damping materials are available only in bulk or molded form, requiring manual fabrication steps and restricting material property control. The Inventors demonstrate a new method for 3D printing viscoelastic materials with specified material properties. This method allows arbitrary net-shape material geometries to be rapidly fabricated and enables continuously varying material properties throughout the finished part. This new ability allows robot designers to tailor the properties of viscoelastic damping materials in order to reduce impact forces and isolate vibrations.

Advantages

- Novel method for device fabrication allows for modifiable, programmable viscoelastic properties

- Fabricates robots that can absorb impact and vibrations for better durability and locomotion

- Method does not require difficult setup and can be used with standard 3D inkjet printers

Publications

MacCurdy, R., Lipton, J., Li, S., & Rus, D. "Printable Programmable Viscoelastic Materials for Robots." In IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2016.

License this technology

Interested in this technology? Connect with our experienced licensing team to initiate the process.

Sign up for technology updates

Sign up now to receive the latest updates on cutting-edge technologies and innovations.