End-to-End Deep Learning Approach to Predict Complex Stress and Strain Fields Directly from Microstructural Images

This technology is a method of determining mechanical behaviors of hierarchical composites using a game-theoretic deep learning approach. This technology has broad applications and may be particularly useful in the study and design of complex biological materials, polymers, ceramics, and metals.

Researchers

-

end-to-end deep learning approach to predict complex stress and strain fields directly from microstructural images

United States of America | Published application

Figures

Technology

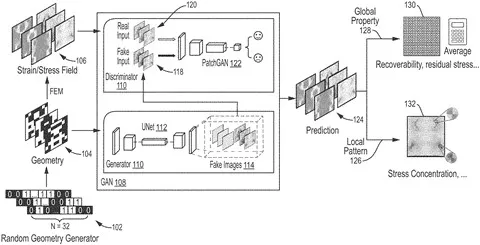

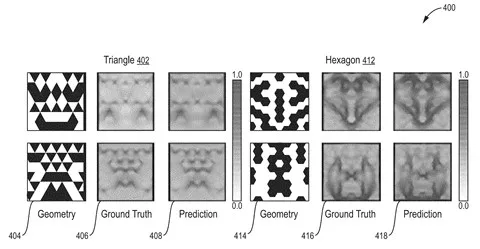

This technology uses material geometry and microstructure to generate strain and stress fields via a deep learning model. The method includes using geometric images as inputs into a generator to produce fake stress or strain field images of composites under mechanical tests. The fake field images are then analyzed in a discriminator neural network to determine if the fake field images represent real stress and strain images produced by multiscale modeling methods (i.e., finite element analysis). This step is repeated until the discriminator can optimize its ability to identify the fake field images produced by the generator. The deep learning model is trained once the discriminator and generator reach Nash equilibrium.

Once the deep learning model is trained, it can be used to predict new field images and bypass conventional numerical modeling.

Problem Addressed

Designing composite materials relies on conjoining different base materials and manipulating complex microstructures. In model-driven design of such materials, calculation of physical properties often relies on multiscale modeling approaches such as finite element analysis (FEM) or molecular dynamics simulations. However, a large gap exists between the design space and physical performance of these materials due to the intractable number of computational measurements.

Deep learning applications incorporating field-based, particle-based, and continuum-based modeling have revolutionized predictions in quantum interactions, and molecular force fields. The machine learning approach of this invention aims to simplify the data needed for accurate prediction of material behavior by translating material composition directly to strain and stress fields.

Advantages

-

Prediction of material behavior is not limited by shape, boundary conditions, or geometrical hierarchy.

-

Provide an efficient method to evaluate physical properties of hierarchical materials directly from analyzing their geometry.

-

Bottom-up design process that can accelerate optimal composite material design.

Publications

Zhenze Yang, Chi-Hua Yu, and Markus J. Buehler. Deep learning model to predict complex stress and strain fields in hierarchical composites. Science Advances. 2021 Apr 09. doi: 10.1126/sciadv.abd7416

Zhenze Yang, Chi-Hua Yu, Kai Guo, et al. End-to-end deep learning method to predict complete strain and stress tensors for complex hierarchical composite microstructures. Journal of the Mechanics and Physics of Solids. 2021 May 31. doi: 10.1016/j.jmps.2021.104506

License this technology

Interested in this technology? Connect with our experienced licensing team to initiate the process.

Sign up for technology updates

Sign up now to receive the latest updates on cutting-edge technologies and innovations.