Fractal Vane Rotors for Rheology Measurements

This technology uses a novel vane cross-sectional structure and detachable textured sample container to measure flow properties of yield stress fluids with high accuracy, improving the process of analyzing yield stress fluids in a range of industrial, commercial, and academic settings. The technology has applications in a wide variety of consumer goods, construction products, and in the field of oil/gas exploration.

Researchers

-

systems, devices, and methods for rheological measurement of yield stress fluids using fractal-like fixtures

United States of America | Granted | 11,698,330

Figures

Applications

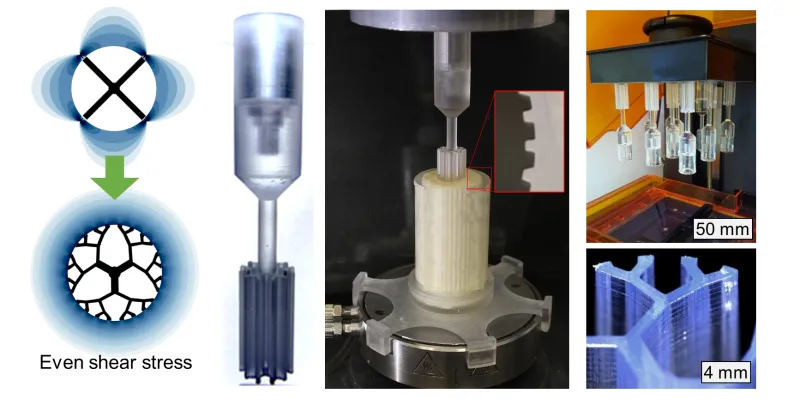

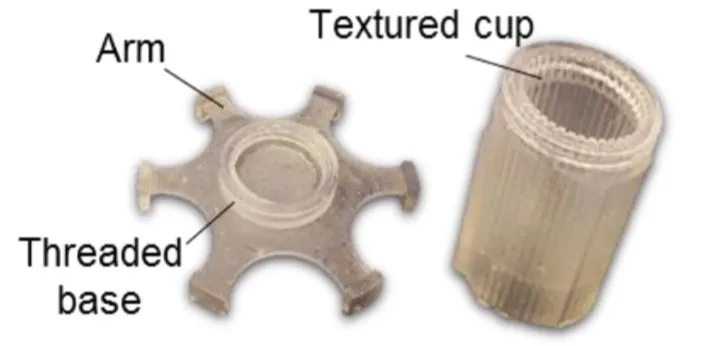

The presented technology comprises a fractal vane structure and a detachable container for the rheometer. The vane rotor consists of a branch-like cross-sectional profile that spreads symmetrically outwards from the center spindle. This fractal layout minimizes projected area, increases surface area contact with fluid, and substantially increases the number of outer contact edges for the vane, creating a more homogeneous stress field. The detachable container is designed with a textured inner surface for enhanced grip of the sample fluid.

Both components for the rheometer can be time efficiently and cost effectively produced by a desktop stereolithography 3D printer, or through other means with further development. Once the instrument is prepared for stress testing, the detachable container can be evenly filled with the yield stress fluid and fastened onto the base of the rheometer. The fractal vane structure then presses into the material, gradually increasing in rotational force. Torque and rotation rate measurements from the rheometer are collected and processed through two composite formulas, which output stress and shear rate calculations for the sample.

Problem Addressed

Yield stress fluids are versatile materials that flow only when sufficient force is applied to them. They have significant applications in a wide variety of consumer goods (e.g., toothpaste, cosmetics, ketchup) and construction products (e.g., cement). A rheometer is used to measure the viscous flow properties of liquids, but current instrumentation poses several challenges to accurately analyzing yield stress fluids.

A rheometer with a fixed container is used to hold a yield stress fluid for assessment. Unfortunately, the rigid design of containers imparts non-homogeneous flow in the sample during the loading process. Furthermore, the multi-blade geometry of typical 4-arm vane structures causes an uneven stress field on a yield stress fluid. Non-homogeneous flow and uneven stress fields both lead to errors in viscosity measurements. This technology addresses these challenges by redesigning the sample container and vane rotor.

Advantages

- Improves quantitative accuracy in measuring yield stress

- Eases the process of loading and cleaning yield stress fluids from sample container

- Decreases manufacturing costs and time for components by using 3D printing

- Multiple versions of improved design are available, allowing for further tailoring to specific material needs (ex. large aggregates, especially high or low torques required, especially fragile material)

Publications

Crystal E. Owens, A. John Hart, and Gareth H. McKinley. Improved Rheometry of Yield Stress Fluids Using Bespoke Fractal 3D Printed Vanes. Journal of Rheology. 2020 March 13.

License this technology

Interested in this technology? Connect with our experienced licensing team to initiate the process.

Sign up for technology updates

Sign up now to receive the latest updates on cutting-edge technologies and innovations.