Vibration Absorber for Power tools

This invention introduces a device capable of minimizing the vibration transfer between power tools and a user’s hand. It has numerous applications in industries that require repetitive use of vibrating machinery, including construction, woodworking, and automotive repair.

Researchers

-

vibration absorber for power tools

United States of America | Granted | 11,583,972 -

vibration absorber for power tools

European Patent Convention | Published application

Figures

Technology

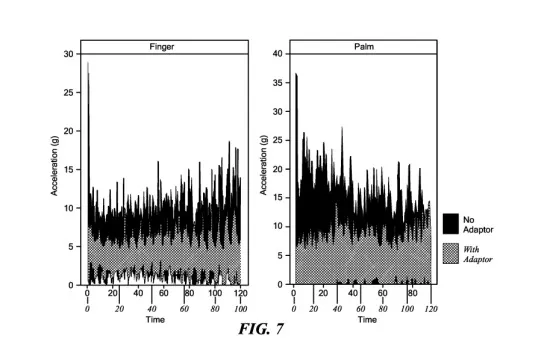

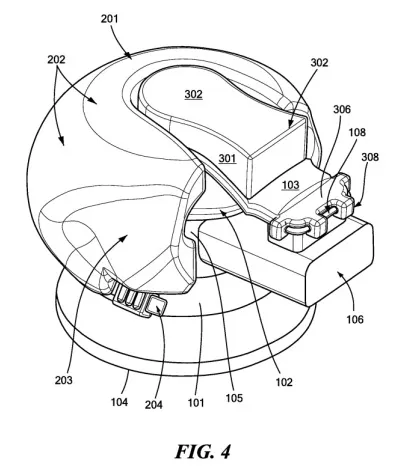

The vibration absorber is comprised of an adjustable adaptor with a core of closed cell liquid filled foams (CCLFF). The CCLFF includes a material containing a viscoelastic polymer (e.g., UV cured acrylate) and a liquid (e.g., polyethene glycol), which can be dispersed into the polymer, with the liquid by volume ranging between 0 to 50 percent. The device additionally comprises of a tool contact surface and a connection mechanism which adheres to the adaptor to the power tool. To prevent liquid from leaking onto the user’s hand or surrounding device, a sealing layer of a viscoelastic material with 0 percent liquid may encricle the CCLFF, enhancing the adhesion of durable, rubber-like materials to the adaptor. To secure the tool to the adaptor, the surface of the selected section can be adhered through either friction fit or clips and interlocks.

Problem Addressed

Hand-arm vibration syndrome arises due to repetitive, vibration-induced trauma, leading to sensory, vascular, and musculoskeletal issues for those affected. In the US alone, around 1.2 million workers are subject to this health hazard daily, necessitating urgent solutions from industry experts to address the problem. Several known methods like glove-based insulators face limitations due to sensory obstructions that impair the user’s grip and control of the tool. The present device addresses this health concern by incorporating a viscoelastic material with a base elastomer, reducing the mass and costs of current vibration dampers in the market while maintaining customizable device properties.

Advantages

-

Reduced costs due to streamlined casting and molding process.

-

More lightweight than traditional vibrational dampening materials.

-

Durable surface for easy cleaning and dust removal.

-

Moldable depression in the material allows for easy gripping.

Publications

- Kandukuri, S., A. Kashyap, and J. Lipton. "Vibration Reduction Using Material Jetted Parts for Sander Grips." Accessed [Date of Access]. https://utw10945.utweb.utexas.edu/sites/default/files/2022/Vibration%20Reduction%20Using%20Material%20Jetted%20Parts%20fo.pdf.

License this technology

Interested in this technology? Connect with our experienced licensing team to initiate the process.

Sign up for technology updates

Sign up now to receive the latest updates on cutting-edge technologies and innovations.